TECHNICAL DESCRIPTION OF THE RENOVATION METHODOTHER RENOVATION METHODS - RENOVATION OF CONNECTIONS IN THE HAT SYSTEM

in accordance with PN-EN 752-5; 13689; 13566-8 and PN-EN ISO 11296-1 and 11296-4

DESCRIPTION OF METHOD

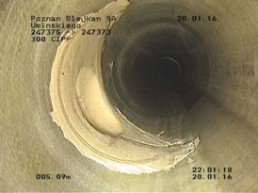

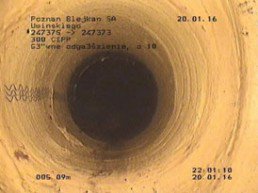

The DrainLCR – Liner (LeteralConnectionRepair) system is used to repair and permanently seal stubs and branches of the main pipeline leading to side inlets, with a diameter of up to 300 mm. Either LCR hat shapes or LCR sleeves can be used. The LCR hat fitting in the main pipeline seals the connection of both pipes only with the rim, while the LCR sleeve is made in the main pipeline similarly to the short sleeve.

EQUIPMENT FOR INSTALLING LINING

- sewer cleaning machine (jetting truck)

- sewer inspection camera

- compressor

- power generator

- EPROS LCR machine

- by-pass devices (pumps, hoses)

REHABILITATION PROCESS OF LATERAL CONNECTIONS

The device can repair in the area of the house connection to the main sewer, using the so-called short sleeve. At the same time, it can repair a section of a house connection with a defined length or install an LCR hat fitting. For this purpose, a preformed, extendable hose is used as a shaping element. This hose, having the shape of a cylinder on the side surface (packer hose) for the main pipe, also has a centrally located cylinder (connector hose), set at an angle of 45° or 90°.

The side stub hose is inserted into the packer hose prior to the repair, together with the LCR sleeve or the LCR hat fitting, which have the same shape of the shaping element. The air is then sucked out of the packer hose and the stub hose. In this way, the material to be repaired (LCR sleeve or LCR hat piece) is prevented from slipping.

The device is moved to the repair site using a fiberglass pole, which is facilitated by the mounted 2 telescopic wheelsets. The device is axially rotated at the repair site by means of wheelsets and a rotation drive motor. A camera is installed in the device for positioning.

LCR System

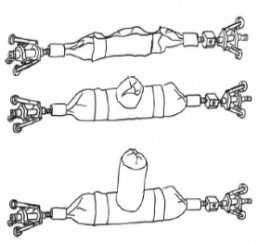

1. Empty packer hose before insertion

2. Packer hose partially inflated with air after its position has been fixed

3. Packer hose fully inflated with air, with installed LCR liner

Then, the lifting mechanism (Pathfinder) is controlled using the control panel. It lifts the basket so that the integrated ring presses against the pipe wall. The packer is now retracted with the fiberglass pole and the ring is inserted into the outlet of the connection. However, if the outlet area is not found, you can move the machine so that the lifting basket slides into the outlet area.

After positioning, the packer hose is inflated, then the stub hose with the sleeve is inserted into the house connection, and the lifting basket is retracted. The insertion delay is achieved by a high strength cable which is guided and braked in the retractor. The completion of insertion into the side port is confirmed by an acoustic signal. After the sleeve hardens, the air is sucked out of the device and then the device can be moved from the place of repair.

BASIC ADVANTAGES OF THE SYSTEM

Reliable way to install:

- Input is only possible when the LCR bin is properly fixed.

- The beeper only sounds when the introduction is complete.

– Technical advantage: only insertion repairs allow repairs at bends and pipe displacement.

– Compliance with the requirements of practice: effective repair is also possible in the presence of groundwater, using only a small amount of equipment.

– Economical: low investment cost as only necessary packers are purchased.

– Practicality: a lightweight, mobile unit that can also be transported in a small car.

– Flexibility: repair can be carried out using a pneumatic pusher or trolley.

–Accessibility: For easier axial insertion of the LCR packers into the channel, they can be pneumatically angled if required.

APPLICATION

Non-pressure sewage networks